With

growing domestic markets for high-end pet feed (and aquafeed), more

companies are moving into these fields. Such a transformation cannot be

made without vacuum sprayers. To meet customers' demand for reliable

high quality equipment, FAMSUN launched its latest product in 2014: the PTZL Series Vacuum Coater.

The PTZL Series Vacuum Sprayer, designed by FAMSUN's European R&D Institute, already made its debut at NAHS&CFIA 2015 in Nanjing, and later its counterpart, the PTZL3000 - first made operational at Huzhou Haihuang Biotechonology Co Ltd in May 2015 - made its first appearance at VICTAM in Cologne, Germany in June 2015.

Technical specifications:

Residue-free spraying

Twin helical rotors ensure even hoisting and spraying; materials outside the separate casing fall evenly. With soft mixing and no dead end, the materials are hoisted without being crushed.

Even spraying

There are numerous pairs of nozzles around the circumference in the outer ring of the upper cover. The liquid is evenly sprayed. See the picture :

Clean discharge

The specially designed cone-shaped discharge door with an inverted cone-shaped lower part shell as well as the small cone apex angle leaves no room for possible residue during discharge.

Reliable seal structure with long service life

The core seal structure adopts a seal solution provided by internationally reputable suppliers. Compared with the products of other manufacturers, the service life of the dynamic seal at the rotor is 10 years rather than merely 3 months; and the seal at the discharge door can also be used for about half a year. Replacement and maintenance is easy.

Quality bought-in machine components from well-known overseas brands

The bought-in components such as Nash or Edwards vacuum pump, DVC vacuum butterfly valve, OMAL proportional valve, WAKI sensor, SEW speed reducer, teamed with FAMSUN's manufacturing engineering and inspection level, provide reliable performance.

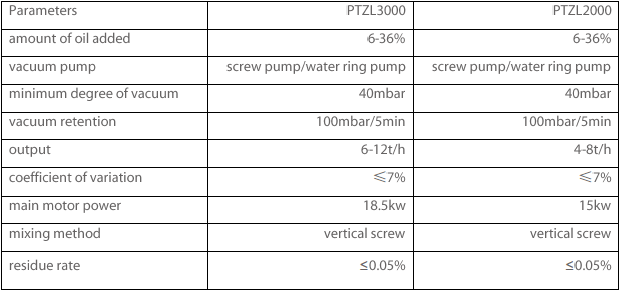

Parameters

Visit the FAMSUN website HERE.

The PTZL Series Vacuum Sprayer, designed by FAMSUN's European R&D Institute, already made its debut at NAHS&CFIA 2015 in Nanjing, and later its counterpart, the PTZL3000 - first made operational at Huzhou Haihuang Biotechonology Co Ltd in May 2015 - made its first appearance at VICTAM in Cologne, Germany in June 2015.

Technical specifications:

- Even liquid spraying (CV ≤7 percent)

- Wide range of liquid-adding ratios with stepless adjustment (6 percent - 36 percent)

- No dead end for mixing with crush-free hoister and residue discharge

- High degree of vacuum (minimum 40mbar)

- Reliable components supplied by internationally famous, trusted brands

- Flexible system that can either be integrated into the control systems or function in automatic/manual mode

Residue-free spraying

Twin helical rotors ensure even hoisting and spraying; materials outside the separate casing fall evenly. With soft mixing and no dead end, the materials are hoisted without being crushed.

Even spraying

There are numerous pairs of nozzles around the circumference in the outer ring of the upper cover. The liquid is evenly sprayed. See the picture :

Clean discharge

The specially designed cone-shaped discharge door with an inverted cone-shaped lower part shell as well as the small cone apex angle leaves no room for possible residue during discharge.

Reliable seal structure with long service life

The core seal structure adopts a seal solution provided by internationally reputable suppliers. Compared with the products of other manufacturers, the service life of the dynamic seal at the rotor is 10 years rather than merely 3 months; and the seal at the discharge door can also be used for about half a year. Replacement and maintenance is easy.

Quality bought-in machine components from well-known overseas brands

The bought-in components such as Nash or Edwards vacuum pump, DVC vacuum butterfly valve, OMAL proportional valve, WAKI sensor, SEW speed reducer, teamed with FAMSUN's manufacturing engineering and inspection level, provide reliable performance.

Parameters

Visit the FAMSUN website HERE.

The Global Miller

This blog is maintained by The Global Miller staff and is supported by the magazine GFMT

which is published by Perendale Publishers Limited.

For additional daily news from milling around the world: global-milling.com

No comments:

Post a Comment